About Us

About Youda Industry

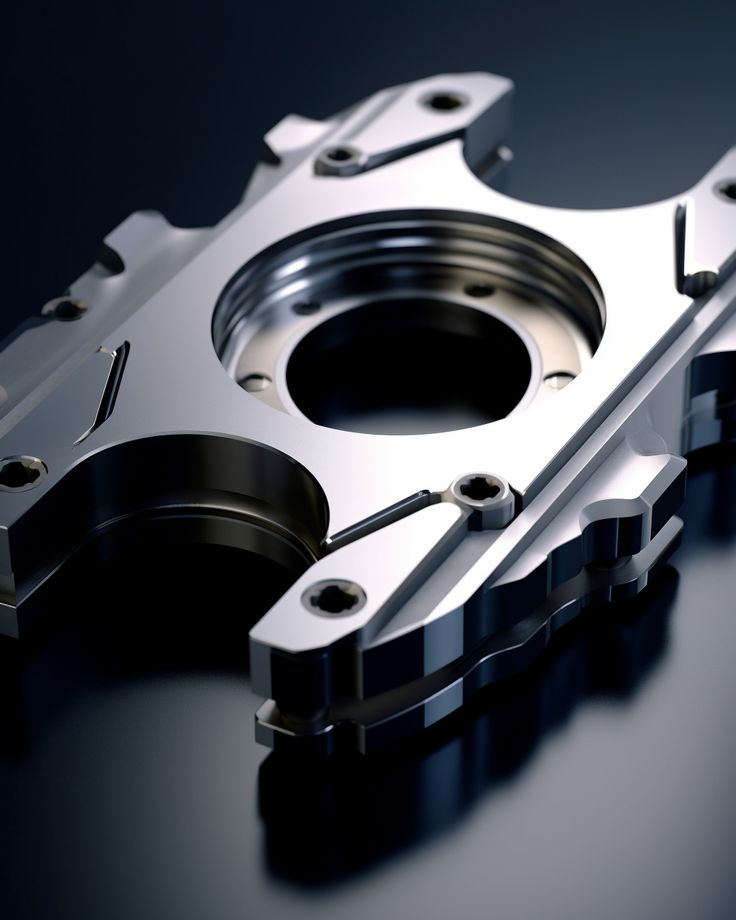

Youda Industry Limited(Shenzhen Henglongda Technology Co., Ltd) is a factory that professionally design and produce Magnesium, Aluminum, Zinc alloy die casting, gravitycasting, aluminum profiles, and CNC machining. We can make the parts with carbon steel, Aluminum, 6061T, 7075T, brass, plastic or stainless steel etc.

Our objective is to develop and produce merchandise to meet your exacts pecifications and offer an extensive range of styles to ensure that we can satisfy your expectations and budget. Our customized products are mainly used on 3C industry, lighting decoration, electrial appliances, auto parts, furniture parts, electric tool, medical equipment, inelligent automation equipment and so on. tis exported to Europe, America, Australia and Southeast Asia etc.

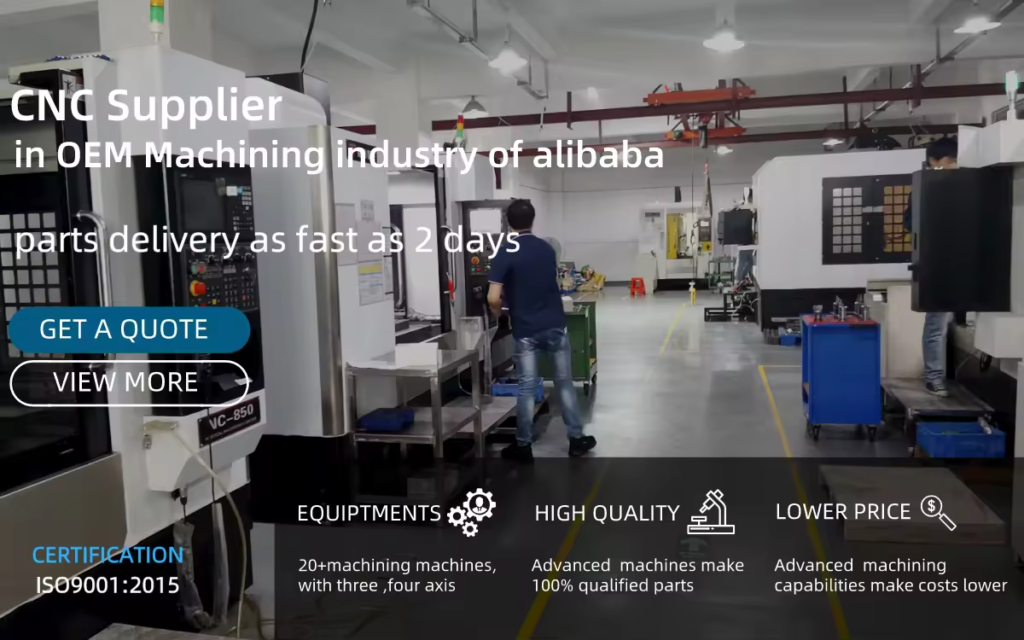

Our company’s production workshop consists of mould department, die-casting department, processing department .CNC department, paint department, etc. Wehave 10 of advanced CNC machining Centers, 4 of CNC turning lathes, CNC drilling lathes, CNC milled machine, stamping machinery, welding equipment etc.

The post-processing department has sets of equipment complete, such as the drill-ing machine, the tapping machine .the cluster drilling machine, buffing machine sand slinger, rolling machine, drawing machine, grinder, punch press, baking varnish and so on.

Contact us to get a quote for your project!

Material

WE can machinning with different Materials

| 1.Main Materials | ||||

| Aluminum | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. | |||

| Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416, etc. | |||

| Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. | |||

| Brass | C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc. | |||

| Copper | C11000, C12000, C12200, C10100, etc. | |||

| Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. | |||

| Plastic | POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc | |||

1) Checking the raw material after they reach our factory——- Incoming quality control ( IQC)

2) Checking the details beforethe production line operated

3) Have a full inspection and routing inspection during mass production—In-process quality

control(IPQC)

4) Checking the goods after they are finished—- Final quality control(FQC)

5) Checking the goods after they are finished—–Outgoing quality control(OQC)

| 2. Surface Treatment | ||||

| Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating Etc. | |||

| Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated | |||

| Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Powder Coated, Nickel Plated Etc. | |||

| Plastic | Plating gold (ABS), Painting, Brushing (Acrylic), laser engraving | |||

Youda industry is a professional factory at independent development and design. Our engineers are skilled at AUTO CAD, PROENGINEER, SOLID, SketchUp. 3D max WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according to your drawings, samples, or just an idea. control of non-standard products and OEM products.